Download

PDF Here

|

Tools

Required:

- 12mm,

14mm, and 30mm sockets

- Adjustable

wrench

- Ratchet

and Breaker Bar

- Regular

Hammer

- 3/16

Diameter Pin Punch

- Snap

Ring Pliers

- 6mm

Allen Wrench

- Gasket

Scraper and/or Cleaner

- Access

to a Press

- Flat

Blade Screwdriver

- Ultra

Gray Silicon Permatex #599512

- Bearing

Grease or Assembly Lube

Guide

Sections:

|

|  21

and 23 Spline 21

and 23 Spline

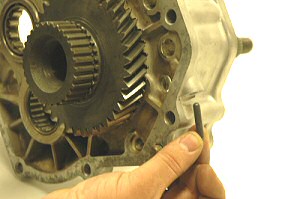

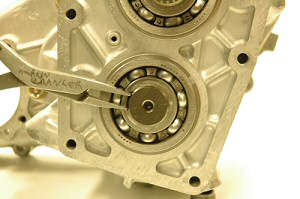

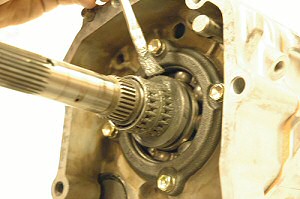

The

photo to the right shows 21 (left) and 23

(right) spline inputs side by side. Carb and

EFI 4cyl Pickup and 4Runners have transmissions

with a 21 splne output. V6 and Turbo trucks

have transmissions with 23 spline outputs.

Both input and output must be the same spline

count. For a single transfer case setup choose

the gear set that matches the spline count

of the transmission you are using. For dual

transfer case setup we recommend using stock

2.28 gears in front and 23 spline 4.70 gears

in the rear case.

Why

mix 21 and 23 spline in the same dual case

on 4cyl trucks?

All

4cyl Toyota trucks have the 21 spline output,

except for the Turbo 5sp trucks. Many people

run dual transfer case setups with 21 spline

inputs in both units of a dual transfer case

without problems. An even stronger setup is

to put a 23 spline gear set in the rear of

a dual transfer case. As the motor power comes

out of the transmission, the torque is more

than doubled when it goes through the first

reduction unit of a dual transfer case. This

means that torque going to the rear input

of a dual transfer case is about double that

of the front. If you purchase your gears and

dual adapter at the same time, get the 23

spline dual adapter and 23 spline gear set.

Using 23 spline components in the rear of

a dual case setup is stronger yet costs the

same as 21 spline components. If you use a

23 spline gear set in the rear, you must have

a dual adapter with a 23 spline coupler. If

you purchased a 21 spline dual adapter, you

can replace the coupler in order to use it

with 23 spline gears. All

4cyl Toyota trucks have the 21 spline output,

except for the Turbo 5sp trucks. Many people

run dual transfer case setups with 21 spline

inputs in both units of a dual transfer case

without problems. An even stronger setup is

to put a 23 spline gear set in the rear of

a dual transfer case. As the motor power comes

out of the transmission, the torque is more

than doubled when it goes through the first

reduction unit of a dual transfer case. This

means that torque going to the rear input

of a dual transfer case is about double that

of the front. If you purchase your gears and

dual adapter at the same time, get the 23

spline dual adapter and 23 spline gear set.

Using 23 spline components in the rear of

a dual case setup is stronger yet costs the

same as 21 spline components. If you use a

23 spline gear set in the rear, you must have

a dual adapter with a 23 spline coupler. If

you purchased a 21 spline dual adapter, you

can replace the coupler in order to use it

with 23 spline gears.

|

| Section

1: Parts List and Overview

4.70

Gear Kit Parts List

21

or 23 Spline input gear w/bearing

Low range gear

Counter shaft gear w/bearing

Transmission output seal

Rear output seal

Front output seal w/felt and retainer

Shift fork clip

Drain and fill plug gaskets (2)

Complete

gasket set (5 pieces)

Marlin Crawler shift knob

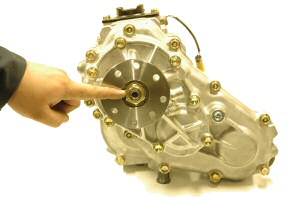

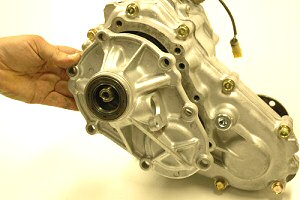

During

disassembly and reassembly we refer to different

transfer case housing sections by number.

The photo below shows each of the covers and

its number.

|

Section

2: Disassembly of Transfer Case

As

you take apart your transfer case we recommend you

label each part as it is removed.

Step 1: Remove

30mm rear nut and flange. |

Step 2: Remove 7 bolts

and cover #4. |

Step 3: Remove 4wd idler

shaft bearing outer snap ring. |

Step 4: Remove 10 bolts

and cover #3. |

Step 5: Pull out and remove 2 oil transfer

tubes. |

Step 6: Remove front drive idler gear.

|

Step 7: Remove speedo drive gear, lock

ball and oil pump gear. Do not loose ball!

|

Step 8: Remove 63/28N rear main shaft

bearing. |

Step 9: Shift into 2wd high. Remove

2wd/4wd shift fork roll pin with 3/16"

pin punch. |

Step 10: Remove 2wd/4wd shift fork and

shift collar. |

Step 11: Remove front output hub.

|

Step 12: Remove front output gear.

|

Step 13: Remove (2) 4wd

output gear cage bearings. |

Step 14: Remove thrust

washer and it's lock ball. |

Step 15: Remove front

output 30mm nut and flange. Remove 4 bolts.

Remove cover #5. |

Step 16: Remove front

output snap ring. |

Step 17: Remove front drive output gear.

|

Step 18: Remove 4 bolts,

remove shifter base (top shift) or block off-plate

(forward shift) depending on model. |

Step 19: Remove 4wd light switch (19mm

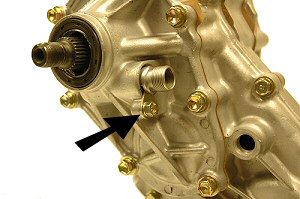

1989-1995 or 22mm 1979-1983) |

Step 20: Remove detent plug, ball and

spring from both sides of upper case. Rotate

case on side, then spring and ball will fall

out. |

Step 21: Remove remaining 4 bolts holding

cover #1. Two bolts are located on the front

side, two are on the rear side. |

Step 22: Remove idler shaft bearing

snap ring. |

Step 23: Remove input shaft bearing

snap ring. |

Step 24: Drive out roll

pins from both shift rails. Pins will fall to

bottom of case. |

Step 25: Slide cover #1 forward and remove.

Retrieve two shift fork roll pins from bottom

of housing. |

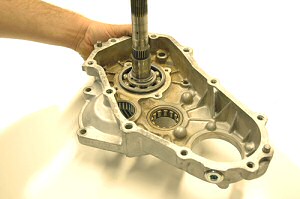

Step 26: Remove input gear. |

Step 27: Remove counter shaft gear.

|

Step 28: Remove pocket bearing from main

shaft. |

Step 29: Remove 2wd/4wd shift fork.

|

Step 30: Remove hi/lo shift fork and

shift collar. |

Step 31: Rotate case 90 degrees right,

tap case lightly to remove shift fork interlock

pin. |

Step 32: Remove 4 bolts and main shaft

bearing cover. |

Step 33: Remove main shaft bearing snap

ring. |

Step 34: Slide cover #2 off of main shaft.

|

Step 35: Remove snap ring from main shaft.

|

Step 36: Remove 6208N main shaft bearing

using press or gear puller. |

Step 37: Remove thrush washer and lock

ball. |

Step 38: Remove low speed gear from

main shaft. |

Step 39: Remove main shaft cage bearing.

|

Step 40: Remove snap rings from input

and counter shaft gears above. The remaining

parts will not be used during reassembly.

|

| |

| Section

3: Reassembly of Transfer Case |

|

Step 41: Apply grease

main shaft race way. Install low speed cage

bearing.

|

Step 42: Install new 4.70 low speed

gear onto main shaft.

|

|

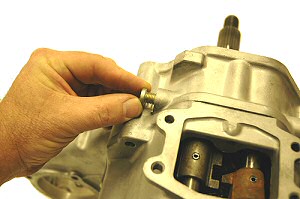

Step 43: Apply grease to the ball hole

and insert ball.

|

Step 44: Apply grease to face of

low speed gear as shown above.

|

Step 45: Slide thrust washer over main

shaft until seated onto face of low speed gear.

Line up notch in washer with ball. |

Step 46: Slide 6308N bearing

onto main shaft. Press bearing until it contacts

thrust washer. Install snap ring onto shaft.

|

Step 47: Slide cover #2 onto main shaft.

|

Step 48: Install bearing retainer

and 4 bolts. Torque to 10 ft/lbs. |

Step 49: Using a grinder or file,

remove inside radius on shift forks(s).

|

Step 50: Top shift

case only. Using a grinder, clearance shift

block as shown above. |

Step 51: On 79-83 models

only, replace C-Clip on 2wd/4wd shift fork with

new clip provided in kit. Clip is not used on

newer cases |

Step 52: Insert roll pin into low

range shift fork. Shaft can go in two ways,

install as shown above. |

Step 53: Install shift

rod, high/low fork and clutch sleeve.

|

Step 54: Grease pocket

bearing inside and out. Insert bearing into

main shaft. |

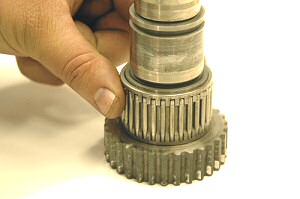

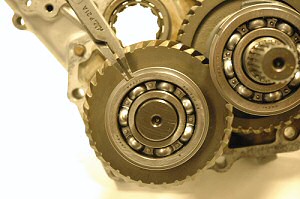

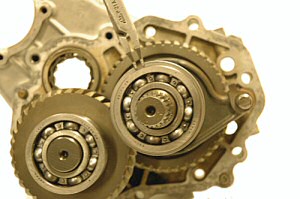

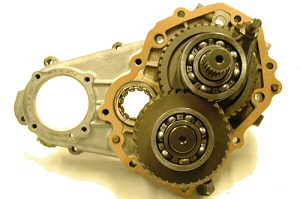

Step 55: Grease both idler and counter

shaft bearings as shown. |

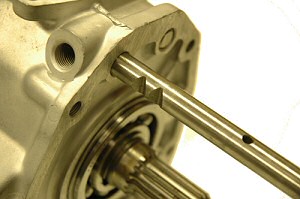

Step 56: Using end

mill or hand grinder clearance case as required

to accept new 4.70 counter shaft. |

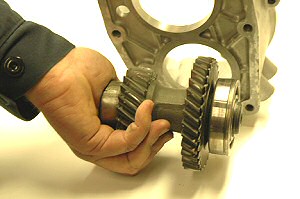

Step 57: Place counter shaft and

bearing in clearanced housing. Rotate counter

shaft to check for proper clearance. Gear should

not contact housing when spun. |

Step 58: Remove counter shaft from

cover #1 number and install into cover #2 as

shown above. |

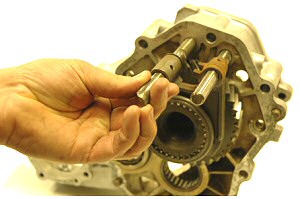

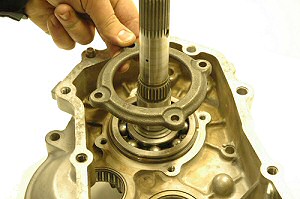

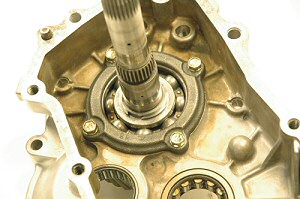

Step 59: Install input gear in main

shaft pocket bearing. |

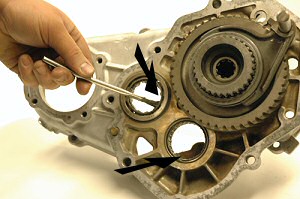

Step 60: Remove snap

ring from counter shaft bearing. |

Step 61: Also remove

snap ring from input gear bearing. |

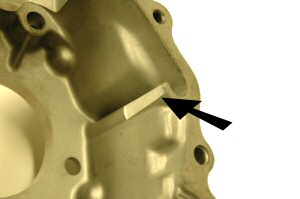

Step 62: Sometimes

it is necessary to clearance cover #1 near the

input gear as shown. Test fit to see if this

is necessary. Clearance up to 1/8" as needed.

|

Step 63: 79-83 cases

only. Install roll pin into shift block. Note

position of shift block fingers and shift rod.

Assemble as shown above. |

Step 64: Place new gasket onto cover

#2. |

Step 65: Slide cover #1 onto cover

#2. Carefully tap cover #1 with hammer until

cover #1 seats on cover #2. |

Step 66: Loosely install two bolts

on front of cover #1. Do not tighten yet.

|

Step 67: Loosely install

two bolts on back of cover #1. Do not tighten

yet. |

Step 68: Install snap ring onto input

gear bearing. |

Step 69: Install snap

ring onto counter shaft bearing. |

Step 70: Install inner

snap ring onto input gear bearing. |

Step 71: Install inner

snap ring onto countershaft gear bearing. Push

shift rod forward. |

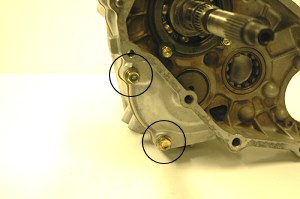

Step 72: Insert interlock pin into

either detent spring hole. (Skip this step if

installing a twin stick) Turn the case on it's

side and tap if needed to get pin into place.

|

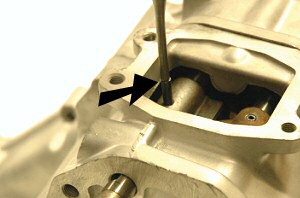

Step 73: Make sure

the interlock pin is all the way into position.

Here is can be seen and is not yet in position.

Push the pin in until it can no longer be seen.

|

Step 74: On 85-88 EFI models only,

place pin just far enough into shift block so

that you can pick up the block. |

Step 75: Use the pin to place shift

block into transfer case. Slide shift rail into

shift block. |

Step 75 (continued): Note position of detent

notches on 2wd/4wd shift rail. |

Step 77: Using a pin punch, drive

pin into place. |

Step 78: Slide front

output gear with bearing into cover #2.

|

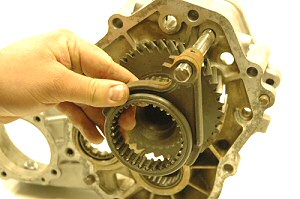

Step 79: Install snap ring around

the outside of the front output gear bearing.

|

Step 80: Light press front output seal

felt and retainer into cover #5. |

Step 81: Turn over cover #5 and grease

inside of rubber seal surface. |

Step 82: Place this gasket onto face

of cover #2. |

Step 83: Install cover #5 using 4

bolts. Torque to 10 ft/lbs. |

Step 84: Apply grease to ball hole

on main shaft and place ball in hole.

|

Step 85: Slide thrust washer onto

main shaft and over ball. Apply grease to face

of thrush washer. |

Step 86: Apply grease to inside and

outside of both both front drive cage bearings.

Slide bearings onto main shaft. |

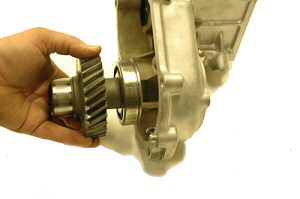

Step 87: Install front transfer drive

gear onto main shaft. |

Step 88: Apply grease to face of

front transfer drive gear. |

Step 89: Slide clutch hub onto main

shaft. |

Step 90: Push roll pin into hi/lo

shift fork just far enough so it will not fall

out. |

Step 91: Install clutch sleeve and

shift fork onto 2wd/4wd shift rail. |

Step 92: Using a 3/16" pin punch,

drive roll pin into shift fork so that it is

flush with the fork. |

Step 93: Install original front drive

idler gear. |

Step 94: Install output shaft rear

bearing. |

Step 95: Slide oil pump drive gear

onto main shaft as shown. |

Step 96: Apply grease to ball hole

and place ball into hole. |

Step 97: Slide speedo drive gear

onto main shaft. |

Step 98: Install oil transfer tubes

as shown. |

Step 99: Place new gasket onto rear

of cover #2. |

Step 100: Apply grease to cage bearing

in rear of cover #3. |

Step 101: Install cover #3 onto the

back of cover #2. Be careful to align oil transfer

tubes in the cover. Install 10 bolts into cover

#3. Torque to 29 ft/lbs. |

Step 102: Install snap ring onto

idler bearing. |

Step 103: Place new gasket onto back

of cover #3. |

Step 104: Remove speedo lock bolts

and tab. Using a screwdriver remove the speedo

drive gear from cover #4. |

Step 105: Remove old seal and install

new seal into cover #4. |

Step 106: Install cover #4 onto the

back of cover #3. Install 7 bolts into cover

#4. Torque to 29 ft/lbs. |

Step 107: Apply grease to speedo

drive gear. |

Step 108: Slide speedo drive gear

into cover #4. |

Step 109: Install speedo gear lock

bolt and tab, torque to 10 ft/lbs. |

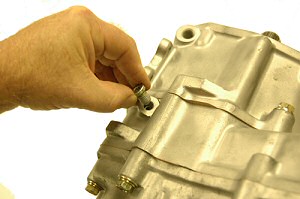

Step 110: With the case on it's side,

drop in one detent ball. |

Step 111: Now drop in a detent spring

after the ball. |

Step 112: Apply silicon to the threads

of the detent plug and install. Flip the case

over onto the other side and install the ball,

spring and plug the same way. |

Step 113: Install 4wd shift light

switch into cover #1. |

Step 114: Apply silicone to the spines

inside both flanges. |

Step 115: Install flange. Note, the

silicone will bulge out just a bit. You should

see a slight bulge on each of the splines.

|

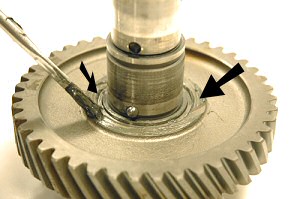

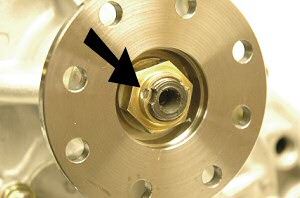

Step 116: Install the main shaft

nuts and tighten to 90 ft/lbs. Using punch,

drive the stake nut into the main shaft as shown

above. Repeat for rear flange. |

| Step

117: Tighten 4 bolts on cover #1 that

were left loose in step #66 & 67. Torque

to 29 ft/lbs. Replace drain and fill plug

washers with ones provided. Install transfer

case into truck. Using the rear fill plug,

fill transfer case with 80/90W GL5 gear oil.

Do not over fill. No brake in is required

for 4.70 gears, we do recommend replacing

the oil after the first 1,000 miles and every

30,000 miles thereafter. Conventional or synthetic

oil may be used.

Torque Specs:

8 X 1.25mm

bolts with 12mm head 10 ft/lbs

10 X 1.25 mm bolts with 14mm head 29 ft/lbs

30mm front and rear flange nuts 90

ft/lbs

|

|